Battery Cabinet Automation Project Process

Utility-scale battery energy storage system (BESS)

Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and conversion – and

Battery Cabinet Automation Controls | HuiJue Group E-Site

As global energy storage capacity surges past 1.5 TWh, battery cabinet automation controls emerge as the unsung heroes. But why do 38% of industrial facilities still report thermal

Scalable outdoor Energy Storage System from 100 kVA / 189

The B-Cab is certified UL 9540A, guaranteeing that it will withstand thermal runaway. Extremely flexible Based on 4 cabinets, and 2 types of battery cabinet (0.5C and 1C), SUNSYS HES L is

Customized Lithium-Ion Battery Storage Cabinets | Wesgar

Rely on Wesgar to produce first-class battery enclosures and take care of your unique needs. Our quality custom lithium-ion battery storage cabinets are skillfully fabricated leveraging our 250+

Automation of Operations in Assembly of Battery Modules in

This paper provides proposals for potential applications where deployment of robotic automation in the battery module assembly context can be explored. The paper investigates

Advanced New Energy Lithium Battery PACK Automated

This state-of-the-art production line achieves seamless automated battery pack production. Spanning an impressive 16 meters, it integrates cutting-edge technology through the following

6 FAQs about [Battery Cabinet Automation Project Process]

What is the Jot battery assembly solution?

Watch the JOT Battery Assembly Solution in action. JOT Automation’s industry-leading battery assembly solution is a fully complete, turnkey solution for battery assembly that is also EV battery compatible. Highlights include automated unpacking of incoming material, testing, welding applications and final-product testing.

What is a battery assembly solution?

The comprehensive Battery Assembly solution can be equipped with an array of options, including unpacking, waste disposal, electrical testing, enclosure and casing assembly, PCB assembly, laser welding and final-product testing. Plus the solution's compartmentalized design ensures high-grade fire safety to keep its processes and surroundings safe.

Why is battery assembly important?

In the competitive world of electric vehicles and energy storage, efficient and precise battery assembly is crucial for meeting high performance and safety standards. At JOT Automation, we provide cutting-edge solutions for battery module assembly and battery pack assembly, ensuring seamless integration and optimized production.

Why do we need automation in battery production?

Demand for lithium-ion batteries is booming. From smartphones and tablets to e-cars: nothing runs without batteries. Accordingly, the required quantities in battery production are increasing rapidly. The solution lies in automation. This is because the manufacture of batteries is technically demanding and requires high safety standards.

What is battery-cell production?

Battery-cell production includes a wide applications, beginning with the validation, management of raw materials to mixing, discrete assembly and more. Put simply, producers face hybrid manufacturing at Not all MES solutions can address this range with typical solutions tailored to either process control.

How KUKA robots are used in the production of lithium-ion battery cells?

In the production of lithium-ion battery cells, special high-precision machines are used for individual production steps. KUKA robots can take over certain key processes such as stacking, loading and unloading, or formation and aging of cells.

More industry information

- The photovoltaic panels have the highest daily power generation

- PV 360 Panel Specifications

- Austrian photovoltaic energy storage equipment manufacturer

- Battery cabinet liquid cooling system design manufacturer

- Solar water pump inverter with built-in battery

- Which type of battery is suitable for photovoltaic panels

- Mongolian local inverter manufacturer supply

- Syria outdoor battery cabinet BMS solution

- How many photovoltaic panels should be used with the inverter

- 74V lithium battery pack

- What are the industrial energy storage systems in Bulgaria

- Swiss photovoltaic panel greenhouse ecological panel manufacturer

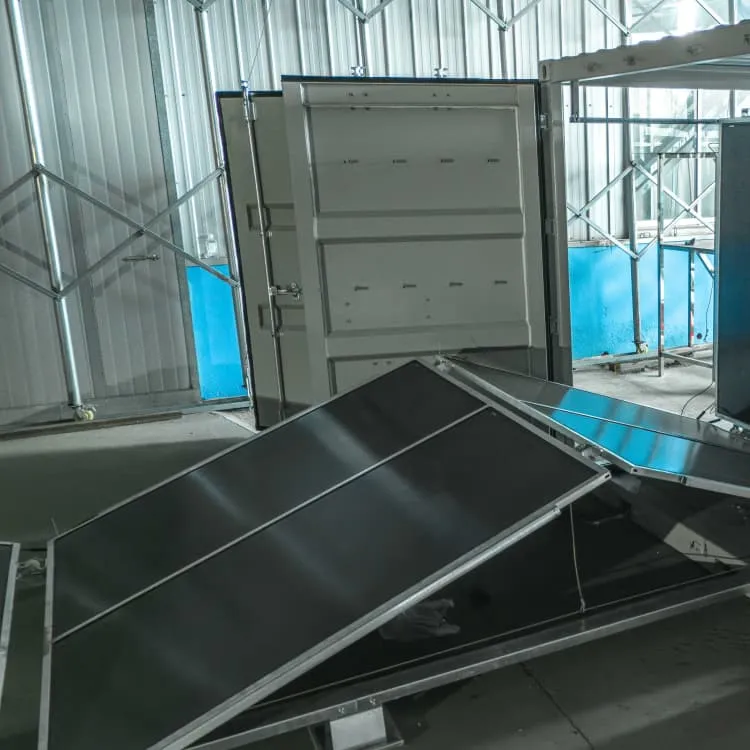

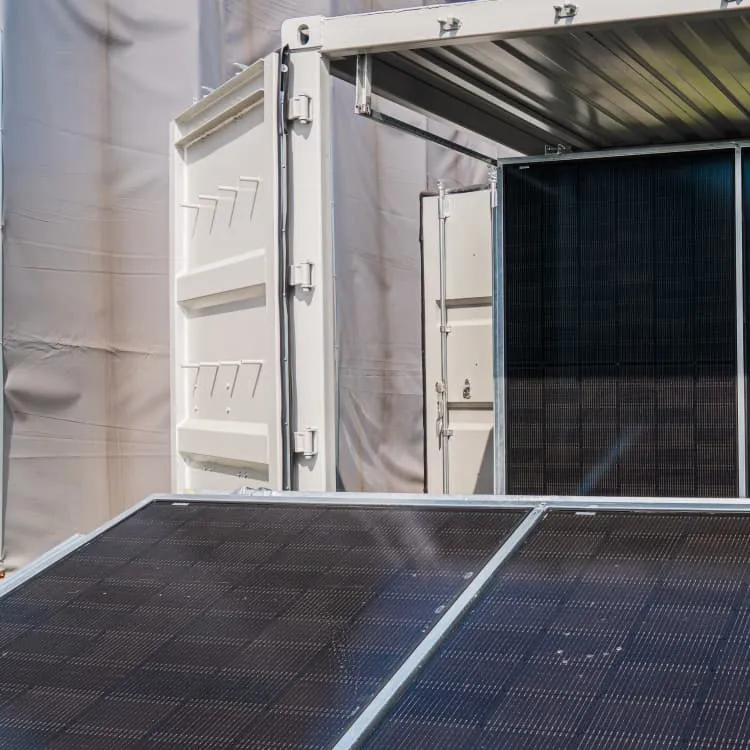

- Spanish mobile photovoltaic folding container wholesale

- Australian substation energy storage power supply price

- Companies producing battery cabinets in Belize

- Energy Storage System of Portugal Electricity Supply Authority

- Energy storage system manufacturers

- 30 kWh lead-acid battery energy storage

- Kazakhstan energy storage BMS price

- Kenya Photovoltaic Energy Storage Equipment Company

- 48v square lithium battery

- How high a temperature can a solar panel withstand

- How much does the communication equipment in the base station cost

- Tunisia Outdoor Mobile Energy Storage Power Plant

- Install solar container house

- How to maintain the battery cabinet

- Eritrea Solar Photovoltaic Module Company