8 4v lithium battery pack production

What Is the Process of Lithium-Ion Battery Pack Assembly Production

So, what are the process flows of a lithium battery pack production line? Here, we break down the primary steps involved in this intricate process. Each step is crucial to

7.4V 3000mAh Lithium Ion Battery Production Enterprise

XUANSN has the capability to custom design a Lithium Ion battery pack to fit your product''s specific needs. From small single-cell packs to large battery packs, XUANSN can design safe

Lithium Battery PACK Production Line Processes and Equipment

The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks, utilizing equipment such as laser

6 FAQs about [8 4v lithium battery pack production]

What is a lithium battery pack?

The Lithium Battery PACK line is a crucial part of the lithium battery production process, encompassing cell assembly, battery pack structure design, production processes, and testing and quality control. Here is an overview of the Lithium Battery PACK line: Cell Types Cells are the basic units that make up the battery pack, mainly divided into:

What is the production process of lithium-ion battery cells?

"Production process of lithium-ion battery cells" , this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain

What makes a custom lithium-ion battery pack unique?

The foundation of any custom lithium-ion battery pack lies in the selection of the integrated cells. Our cell selection for custom packs involves: Lithium-ion cell advancements continue expanding performance boundaries yearly. Leveraging state-of-the-art cell technology is crucial for maximizing custom pack capabilities.

How do you make custom lithium-ion battery packs?

Key Takeaway: Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent engineering, prototyping, certification, production planning, and lifecycle support.

What is the cell assembly process in lithium batteries?

The cell assembly process in lithium batteries involves arranging and connecting individual cells to form a complete battery pack. This includes cell sorting, mounting, resistance and laser welding, and integrating the Battery Management System (BMS).

What are the production processes of a battery pack?

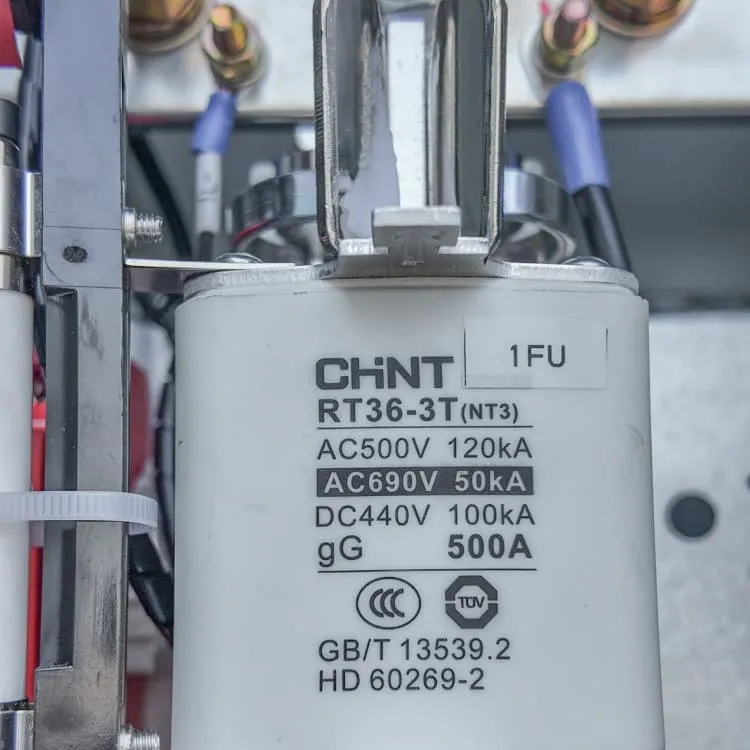

Outer Packaging: Provides physical protection. Output Interfaces: For connecting the battery pack with external devices. Production processes cover cell selection and grouping, welding, assembly, aging testing, inspection, and packaging. Assembly Production Line The process flow of the PACK production line includes:

More industry information

- 12 volt photovoltaic panels can charge large batteries

- Do photovoltaic panels generate electricity in the morning and evening

- Are there any energy battery cabinets on site in Algeria

- Lead-acid solar energy storage

- Morocco $900 million energy storage project

- Huawei s photovoltaic panels on Spanish roofs

- Energy Storage Container Scale Analysis

- Input voltage fully supports inverter

- What brands of solar power generators are used

- Ghana Communication Base Station

- Slovakia flywheel energy storage

- Photovoltaic energy storage inverter parameters

- Russian industrial energy storage battery assembly

- Huawei s approach to wind power energy storage

- Energy Storage Battery Operation Management

- Energy storage charging station cost calculation

- Ghanaian household energy storage battery

- Huawei inspects all-vanadium redox flow batteries

- Liquid Cooling Energy Storage Prices in Iceland

- Türkiye s new energy storage scale

- What are the energy storage power stations in Samoa

- Power system energy storage parameters

- Japan s distributed energy storage lithium battery

- 76 degree battery cabinet cost

- Afghanistan photovoltaic container manufacturer

- Photovoltaic solar power generation 24-hour energy storage power generation

- Does low resistance of photovoltaic panels affect power generation