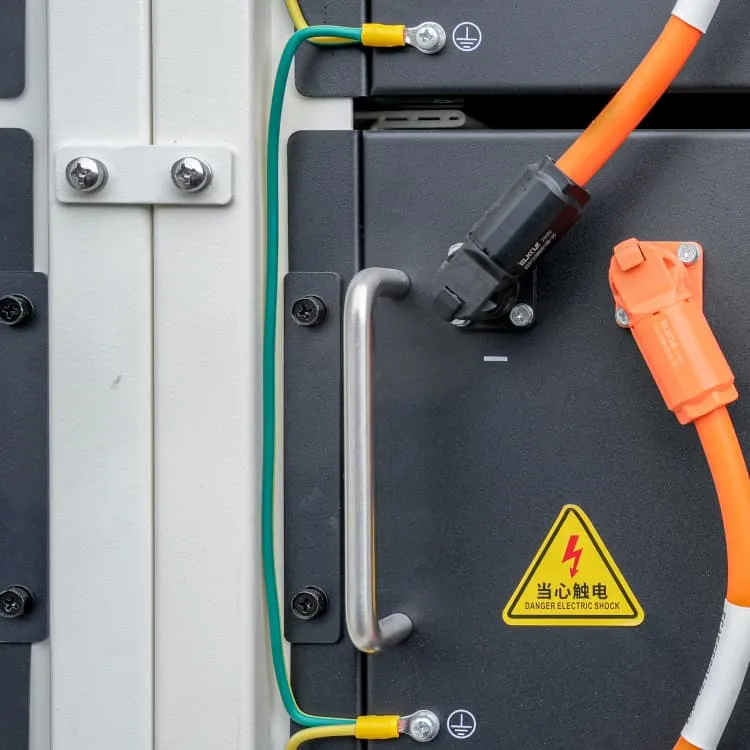

Pack battery and system assembly

Battery Pack Assembly: Techniques and Materials Used

Electric vehicles rely on lithium-ion batteries for energy storage, making the battery pack the heart of an EV. Its assembly involves intricate processes to ensure reliability, energy

Battery Pack Assembly Equipment Manufacturer, Battery Test

Founded in 2011, WinAck Battery has always focused on the R&D and production of battery pack assembly equipment and battery testing equipment. More professional, we can provide

Battery Pack Designer''s Guide: From Beginner to Pro [With

Battery pack development progresses through systematic integration of electrochemical cells, module assemblies, and pack-level components. Each component level contributes specific

EV Car Battery Assembly,Electric Bike Battery Assembly

We also supply all kinds of EV Car Battery Assembly,Electric Bike Battery Assembly for you! We can assure our customers of our products with high quality,best services and a reasonable price.

How to Assemble a Lithium Battery Pack: Step-by-Step Guide for

In this guide, we''ll walk you through everything you need to know – from the basics of what a battery pack is, to the tools and materials required, the step-by-step assembly

How to Assemble a Battery Pack with a BMS Module | Step-by

Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed assembly instructions, and testing

Lithium-ion Battery Pack Manufacturing Process & Design

At the heart of the battery industry lies an essential lithium-ion battery assembly process called battery pack production. In this article, we will explore the world of battery

Mastering the Battery Pack Assembly Process: A Comprehensive

The battery pack assembly process is a meticulously planned sequence of steps that transforms individual components into a fully functional battery pack. It begins with the

Battery Module: Manufacturing, Assembly and Test Process Flow.

In this article, we will look at the Module Production part. The Remaining two parts Pack Production and Vehicle Integration will follow in the next articles. 1. Module Production.

6 FAQs about [Pack battery and system assembly]

What is a battery pack assembly process?

The battery pack assembly process is a meticulously planned sequence of steps that transforms individual components into a fully functional battery pack. It begins with the procurement of high-quality materials, including battery cells, BMS, wiring, and protective casings.

What are the three parts of battery pack manufacturing process?

Battery Module: Manufacturing, Assembly and Test Process Flow. In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell Finishing. Article Link In this article, we will look at the Module Production part.

What is the battery pack manufacturing process?

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

What is battery module assembly process?

The battery module assembly process is a crucial step in the battery pack manufacturing process, where individual battery cells are grouped into modules. This stage enhances efficiency, safety, and performance by integrating electrical connections, thermal management systems, and safety features.

How do you assemble a battery pack?

Assembling a battery pack involves several critical steps to ensure its performance and safety: The first step involves gathering and inspecting all necessary components, such as battery cells, the Battery Management System (BMS), wiring, connectors, and casings. This ensures that only high-quality, defect-free parts are used.

What is a battery pack?

Battery packs will increasingly incorporate features tailored for ultra-fast charging and wireless charging technologies, driving innovation in both EVs and EV charging networks. Battery pack assembly is at the heart of the EV revolution, shaping the performance, safety, and sustainability of electric vehicles.

More industry information

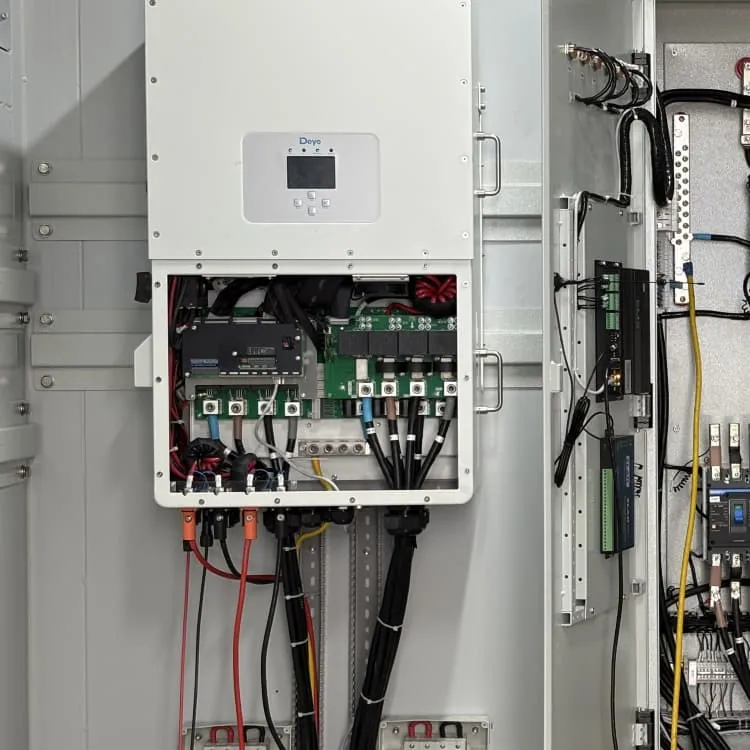

- Photovoltaic off-grid high-frequency inverter

- South African charging inverter manufacturer

- Energy storage power station temperature warning method

- Base Station Site Network Status Analysis

- Home GEL Battery Inverter

- Home photovoltaic power station combiner box

- Which lithium battery is best for energy storage in Seychelles

- Advantages of frequency regulation of flywheel energy storage system

- Energy storage battery planning and implementation

- Huawei solar panel components

- Guyana 5G communication base station battery energy storage

- Chilean Island Solar Power Generation Home Franchise

- Centralized photovoltaic power station energy storage price

- Nordic Industrial Frequency Off-Grid Inverter

- Spanish solar water pump inverter

- Can off-grid inverters be connected in parallel

- Cuba photovoltaic inverter prices

- Outdoor battery cabinet fire protection distance

- Gambia Outdoor Power System

- How much is the maximum power of the solar all-in-one machine

- How much power does Togo Communications 5G base station generate

- Comoros Photovoltaic Folding Container BESS Wholesale

- Photovoltaic borosilicate solar panels

- Equatorial Guinea lithium battery energy storage equipment manufacturer

- How many watts of solar energy are used in your home

- Photovoltaic ultra-thin solar panels

- Home Inverter Buying Guide