Photovoltaic panel manufacturers cost-effectiveness

How Solar Panel Efficiency and Cost Changed Over Time

Solar panel technology has undergone a remarkable transformation, reshaping the renewable energy landscape. Over the past decades, two key factors have driven this revolution: the

How Solar Panel Efficiency and Cost Changed Over Time

By the 2000s, advancements in technology and manufacturing reduced prices to about $10 per watt. A key principle in this decline is Swanson''s Law, which states that the price of solar

Solar Manufacturing Cost Analysis | Solar Market Research & Analysis | NREL

Input data for this analysis method are collected through primary interviews with PV manufacturers and material and equipment suppliers. This approach enables NREL to

Efficiency, Materials, and Cost-Effectiveness of Photovoltaic Solar Panels

Power conversion efficiency (PCE) is a key feature of solar PV, influenced by factors such as the material used in the PV cell, insolation, temperature, and shading. Ongoing

Cost Breakdown of a Solar Panel: From Manufacturing to Market

This article provides an in-depth analysis of the costs associated with solar panels, including manufacturing expenses, marketing and distribution efforts, regulatory compliance,

How solar panel cost and efficiency have changed over time

Over time, photovoltaic (PV) power generation technology has continued to evolve, allowing the cost of solar panels to be reduced and PV power generation to become more and

Top Solar PV Panel Manufacturers in India | 2025 Guide

🇮🇳 Leading Solar PV Panel Manufacturers in India (2025) India''s solar manufacturing industry has seen exponential growth. Here''s an overview of some of the most reputed solar

Efficiency, Materials, and Cost-Effectiveness of Photovoltaic Solar

Power conversion efficiency (PCE) is a key feature of solar PV, influenced by factors such as the material used in the PV cell, insolation, temperature, and shading. Ongoing

A literature review on Improvement of Weather prediction by

However, despite these advancements, several challenges remain on the path to maximizing solar panel efficiency. Issues such as material degradation, manufacturing scalability and cost

6 FAQs about [Photovoltaic panel manufacturers cost-effectiveness]

Why is effective control of solar PV costs important?

Effective control of these costs is necessary for maintaining competitiveness and growth. Profitability Analysis Year on Year Basis: The proposed solar PV module plant, with a capacity of 1,000 MW (1 GW) solar PV module annually, achieved an impressive revenue of US$ 169.0 million in its first year.

How are PV production costs modeled?

The costs of materials, equipment, facilities, energy, and labor associated with each step in the production process are individually modeled. Input data for this analysis method are collected through primary interviews with PV manufacturers and material and equipment suppliers.

How did our solar PV module manufacturing plant's financial model work?

Our solar PV module manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs.

How do market factors affect the cost of solar panels?

The impact of market factors on the cost of solar panels is nuanced, influenced by supply and demand dynamics, technological advancements, and the competitive landscape. These elements collectively dictate the pricing strategies of manufacturers and ultimately the affordability of solar technology for consumers.

Will solar panels become more cost-effective?

As technology evolves, it’s likely that residential solar panels and commercial solar panels will become even more cost-effective, with efficiency rates that surpass today’s models.

What is PV system cost model (pvscm)?

The total cost over the service life of the system is amortized to give a levelized cost per year. In the PV System Cost Model (PVSCM), the owner’s overnight capital expense (cash cost) for an installed PV system is divided into eight categories, which are the same for the utility-scale, commercial, and residential PV market segments:

More industry information

- Double-glass module sales

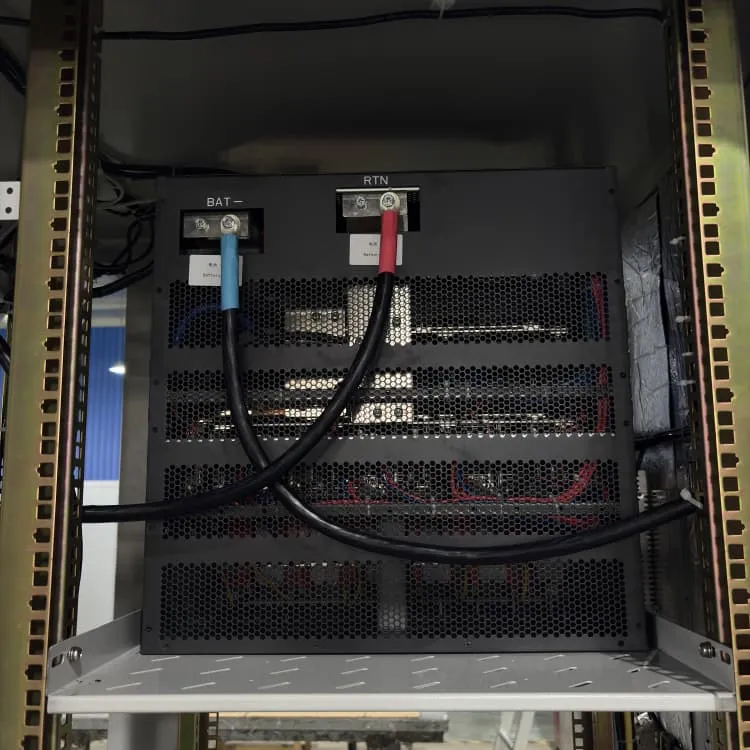

- Energy storage cabinet air cooling system price

- American explosion-proof photovoltaic panel manufacturer

- Gabon 5G communication base station energy storage system construction plan

- Is lithium battery the future trend of energy storage

- Is container energy storage cabinet used in large quantities

- Grid-level energy storage container

- New Zealand container energy storage box sales

- 24v AC230v 500W inverter

- How many kw is a 30t inverter equivalent to

- Does a 6kw inverter consume a lot of power

- How much does a household energy storage battery cost in Croatia

- Island water pump inverter factory direct sales

- Turkmenistan Su photovoltaic container

- Battery energy storage system price

- Large independent energy storage equipment manufacturers

- Huawei Yaounde Large Energy Storage Cabinet

- Base Station Power Project Implementation Plan

- Dominican photovoltaic panel prices

- Which German energy storage container fire protection system is cheap

- Is the cost of wind and solar complementary communication base stations high

- Chile orders lithium battery packs

- Huawei s Belgian solar panels

- Peruvian Island Photovoltaic Power Generation Inverter

- Differences between monocrystalline and polycrystalline photovoltaic panels

- German lithium battery station cabinet 125kWh for sale

- Outdoor Power Portable Energy Storage