Temperature difference of liquid-cooled energy storage cabinet

Intelligent energy storage liquid-cooled integrated cabinet

Product Overview The 215kW Intelligent Energy Storage Liquid-Cooled Integrated Cabinet is specifically designed for commercial and industrial scenarios. It uses liquid-cooling

Energy storage liquid cooling cabinet manufacturing

While liquid cooling systems for energy storage equipment, especially lithium batteries, are relatively more complex compared to air cooling systems and require additional components

What is the temperature of the energy storage cabinet liquid cooling

The temperature of an energy storage cabinet liquid cooling cabinet typically ranges from 18°C to 25°C during optimal operation, maintaining efficiency and performance,

372kWh Liquid Cooling High Voltage ESS | GSL ENERGY

Independent temperature control adoption of centralized refrigeration, multistage pipelines, and co-current flow in parallel flow design facilitates a temperature difference of 3 ℃ for the container.

The Ultimate Guide to Liquid-Cooled Energy Storage Cabinets

Liquid cooling is a method that uses liquids like water or special coolants to dissipate heat from electronic components. Unlike air cooling, which relies on fans to move air

Efficient Cooling System Design for 5MWh BESS Containers:

Discover the critical role of efficient cooling system design in 5MWh Battery Energy Storage System (BESS) containers. Learn how different liquid cooling unit selections impact

Study on uniform distribution of liquid cooling pipeline in container

The above studies have explored the flow uniformity of liquid cooling plates, but in the BESS liquid-cooling system, the flow uniformity of the primary, secondary, and tertiary

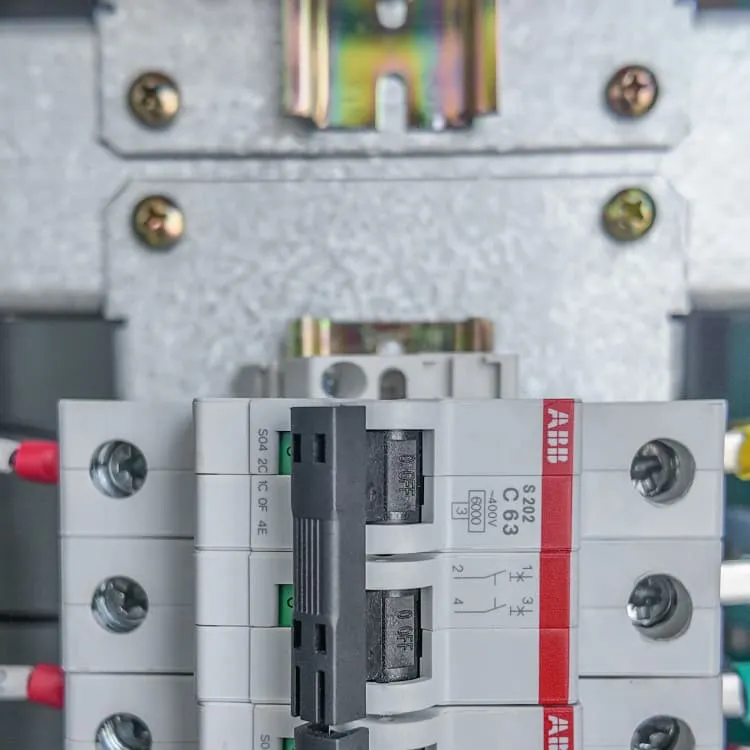

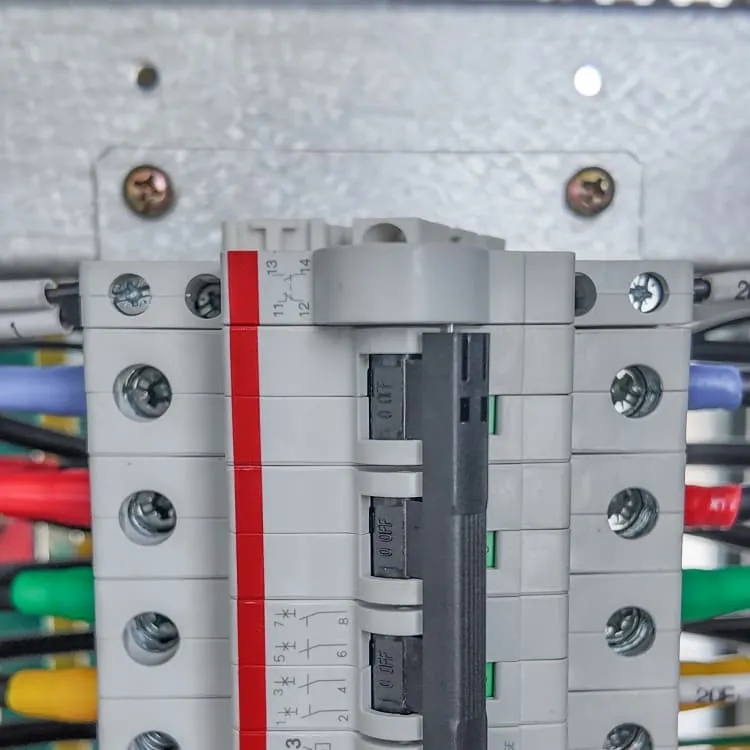

ECO-E233LS | SHANGHAI ELECNOVA ENERGY STORAGE

The all-in-one liquid-cooled ESS cabinet adopts advanced cabinet-level liquid cooling and temperature balancing strategy.The cell temperature difference is less than 3°C, which further

What is the temperature of the energy storage cabinet liquid

The temperature of an energy storage cabinet liquid cooling cabinet typically ranges from 18°C to 25°C during optimal operation, maintaining efficiency and performance,

Air-cooled ESS Cabinet | SHANGHAI ELECNOVA ENERGY STORAGE

The all-in-one liquid-cooled ESS cabinet adopts advanced cabinet-level liquid cooling and temperature balancing strategy.The cell temperature difference is less than 3°C, which further...

Temperature difference of liquid-cooled energy storage cabinet

The all-in-one liquid-cooled ESS cabinet adopts advanced cabinet-level liquid cooling and temperature balancing strategy. The cell temperature difference is less than 3°C, which

Air-cooled Hybrid Solar ESS Cabinet | SHANGHAI ELECNOVA ENERGY STORAGE

The all-in-one liquid-cooled ESS cabinet adopts advanced cabinet-level liquid cooling and temperature balancing strategy.The cell temperature difference is less than 3°C, which further...

6 FAQs about [Temperature difference of liquid-cooled energy storage cabinet]

What is eco-e233ls liquid-cooled ESS cabinet?

ECO-E233LS Liquid-cooled ESS Cabinet - JIANGSU ELECNOVA ELECTRIC CO., LTD. The all-in-one liquid-cooled ESS cabinet adopts advanced cabinet-level liquid cooling and temperature balancing strategy. The cell temperature difference is less than 3°C, which further improves the consistency of cell temperature and extends the battery life.

What is a composite cooling system for energy storage containers?

Fig. 1 (a) shows the schematic diagram of the proposed composite cooling system for energy storage containers. The liquid cooling system conveys the low temperature coolant to the cold plate of the battery through the water pump to absorb the heat of the energy storage battery during the charging/discharging process.

How to choose a compressor for a container energy storage battery?

In view of the temperature control requirements for charging/discharging of container energy storage batteries, the selection of the compressor is based on the rated operating condition of the system at 45 °C outdoor temperature and 18 °C water inlet temperature to achieve 60 kW cooling capacity.

Do cooling and heating conditions affect energy storage temperature control systems?

An energy storage temperature control system is proposed. The effect of different cooling and heating conditions on the proposed system was investigated. An experimental rig was constructed and the results were compared to a conventional temperature control system.

Is liquid cooling better than air cooling?

Liquid cooling has a higher heat transfer coefficient than air cooling, with the continuous improvement of battery power density, liquid cooling will become the mainstream cooling method in the future . For the cooling terminal, some researchers have carried out many studies on the design of cold plates [, , ].

How much energy does a container storage temperature control system use?

The average daily energy consumption of the conventional air conditioning is 20.8 % in battery charging and discharging mode and 58.4 % in standby mode. The proposed container energy storage temperature control system has an average daily energy consumption of 30.1 % in battery charging and discharging mode and 39.8 % in standby mode. Fig. 10.

More industry information

- Serbia photovoltaic panel power supply system manufacturer

- Huawei Samoa Energy Storage Construction Project

- 5 g base station electricity consumption at night

- Turkmenistan large energy storage cabinet supplier

- Which flow battery manufacturer is best for Egypt s communication base stations

- What company is the Fiji energy storage project for

- Energy storage battery prices in Ireland

- China Solar Energy Storage Cabinet Project

- Indonesia Energy Storage New Energy Electricity Cost

- Monaco lithium battery energy storage cabinet installation factory is running

- Photovoltaic solar panels factory direct sales

- What is container photovoltaic energy storage

- Ecuadorian stacked energy storage battery manufacturer

- What size inverter should I use for a 12 volt electric shock device

- Togo Portable Power Storage

- East Africa Industrial Energy Storage System

- Energy storage container installation costs

- Huawei Malaysia energy storage battery manufacturer

- Do microgrids necessarily need energy storage

- Saint Lucia photovoltaic panel manufacturer

- Inverter safety features and prices

- Advantages and disadvantages of lead-carbon energy storage batteries

- Moldova small power inverter

- Solar power generation home mode

- Armenia villa solar power generation system

- Thin-film photovoltaic power station inverter

- Syrian organic photovoltaic inverter