Production of 8 4v lithium battery pack

Lithium Ion Battery 44.4V 15Ah Production Enterprise

XUANSN has the capability to custom design a Lithium Ion battery pack to fit your product''s specific needs. From small single-cell packs to large battery packs, XUANSN can design safe

How to Build a Lithium Ion Battery Pack: Expert Guide for Engineers

Building lithium-ion battery packs requires systematic engineering across multiple disciplines, from cell selection to safety compliance. Here are the essential insights every

Zeee 8.4V 3000mAh NiMH Battery High Power RC Battery with

Zeee is the leading manufacturer of high rate discharging lipo battery around the world, we are focusing on research, development and production of Li-Polymer batteries for over decades.

iCreatin 8.4V 1A Power Adapter Li-ion Battery Charger with LED

Output: DC 8.4V 1A Battery Charger (Suitable for 7.2V 7.4V 8.4V 2-string Lithium Battery Pack) Output interface: 5.5 mm (built-in leaf spring, Compatible with 5.5x2.1mm ) fore Bid, be sure

What Is the Process of Lithium-Ion Battery Pack Assembly Production

So, what are the process flows of a lithium battery pack production line? Here, we break down the primary steps involved in this intricate process. Each step is crucial to

5 FAQs about [Production of 8 4v lithium battery pack]

What is the production process of lithium-ion battery cells?

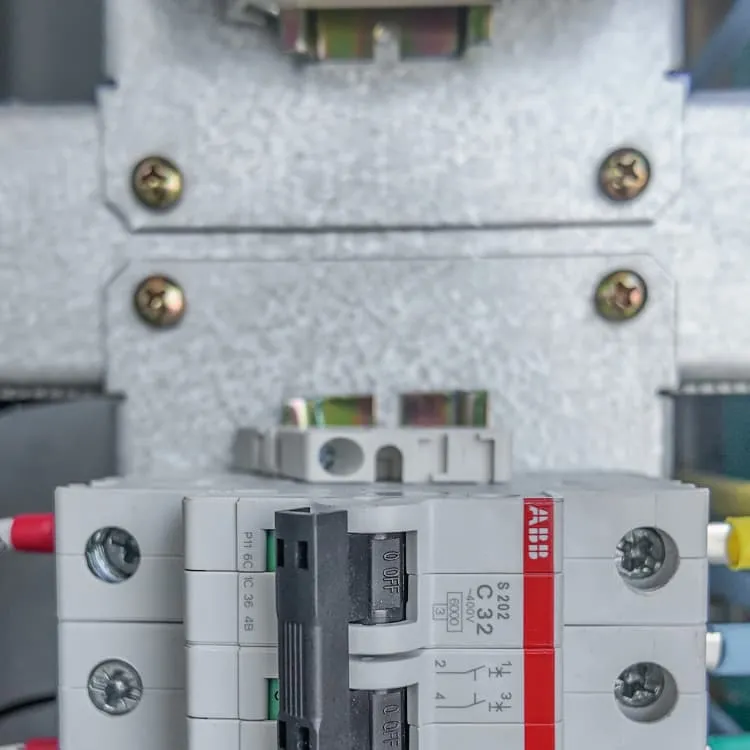

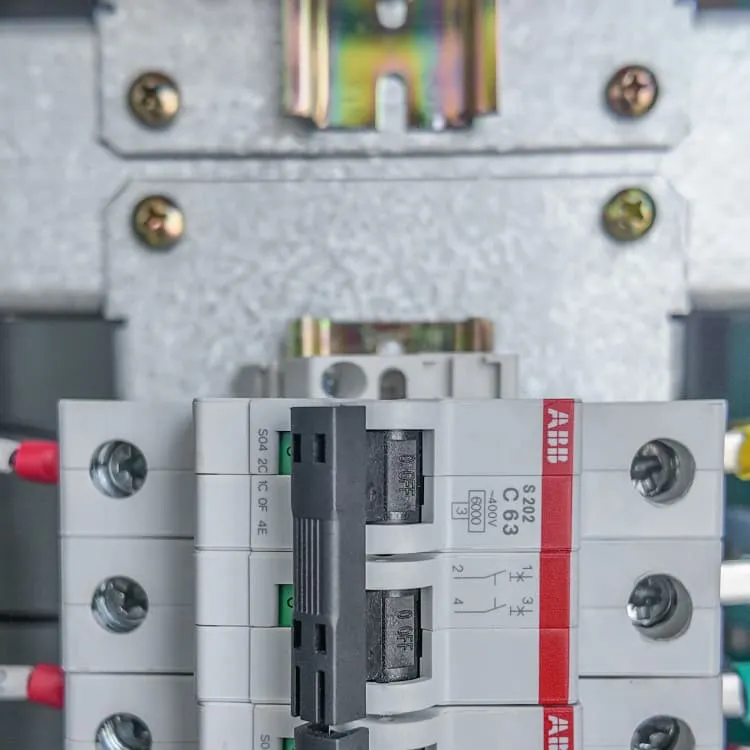

"Production process of lithium-ion battery cells" , this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain

What makes a custom lithium-ion battery pack unique?

The foundation of any custom lithium-ion battery pack lies in the selection of the integrated cells. Our cell selection for custom packs involves: Lithium-ion cell advancements continue expanding performance boundaries yearly. Leveraging state-of-the-art cell technology is crucial for maximizing custom pack capabilities.

How do you make custom lithium-ion battery packs?

Key Takeaway: Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent engineering, prototyping, certification, production planning, and lifecycle support.

What is the process chain for the production of battery modules?

, this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain Overview of the production sequence from cell to system

Are competencies transferable from the production of lithium-ion battery cells?

In addition, the possible transferability of competencies from the production of lithium-ion battery cells is illuminated. 2ndedition ISBN 978-3-947920-29-7 Ed. PEM of RWTH Aachen University & VDMA

More industry information

- Central Europe power plant energy storage project

- 250kW flywheel energy storage equipment

- Taipei New Energy Photovoltaic Energy Storage Company

- Kiribati Communications Photovoltaic Base Station Company

- Which brand of photovoltaic energy storage cabinet is good to use

- How to calculate the power and current of battery cabinet

- Oman is an energy storage battery manufacturer

- Uruguayan photovoltaic panel n-type manufacturer

- Egypt Energy Storage Cabinet Battery Assembly Factory

- The impact of superconductivity on energy storage batteries

- Myanmar s future new energy storage battery

- Ukraine Electric Energy Storage Wind Power Lithium Battery

- Mali solar photovoltaic panel company

- San Marino Photovoltaic Energy Storage Industrial Park

- How big a battery should I use for a 1 kW solar panel

- Cost of energy storage photovoltaic equipment in Albania

- 250kw mobile energy storage power supply

- Huijue 3kW portable power supply

- Chilean Cadmium Telluride Photovoltaic Curtain Wall

- Energy storage battery price trends and trends

- Advantages and disadvantages of photovoltaic string central inverter

- Bhutan Power Storage

- Huawei Costa Rica energy storage lithium battery

- Mobile solar container photovoltaic power station

- Northern Cyprus lithium energy storage power supply price

- United Arab Emirates stacked energy storage cabinet photovoltaic

- Advantages of multi-voltage inverters