Which battery to choose when making lithium battery pack

How to Choose the Right Li-ion Battery Pack for Your Needs

Selecting the right Li-ion battery pack depends on voltage, capacity, chemistry, discharge rate, and application. By understanding these factors, you can ensure optimal performance, safety,

What Is a Lithium-Ion Battery Pack? Types, Voltages & How to Choose

Learn the differences between 18650, 21700, and custom lithium-ion battery packs. Understand voltages like 11.1V and 14.8V, and how to choose the right Li-ion battery pack for

How to Choose Lithium Battery Solutions: Expert Guide for

FAQs Q1. What factors should I consider when choosing a lithium battery for industrial applications? When selecting a lithium battery for industrial use, consider your specific energy

How to Choose the Right Lithium Battery Cells: A Guide for DIY Battery

In this guide, we''ll walk you through the essential factors to consider when choosing lithium battery cells and how to make the right choice for your needs. What Are

How to Make a 12V Battery Pack Using 18650 Lithium-ion Cells

Building a 12V battery pack with 18650 batteries has become a popular choice due to their high energy density and reliability. With our step-by-step instructions, even beginners can successfully

How to make lithium ion battery packs? | Semco Infratech

From choosing the correct cells to designing your own battery pack, it includes all the steps for building custom lithium battery packs. Lithium batteries have increasingly found

Battery Cells vs. Modules vs. Packs: How to Tell the Difference

Battery Cells vs. Modules vs. Packs: How to Tell the Difference Batteries drive almost everything—from pocket-size gadgets to electric vehicles (EVs) and grid storage. Yet "battery"

What Is a Lithium-Ion Battery Pack? Types, Voltages & How to

Learn the differences between 18650, 21700, and custom lithium-ion battery packs. Understand voltages like 11.1V and 14.8V, and how to choose the right Li-ion battery pack for

Diy Lithium Batteries: How To Build Your Own Battery Packs

Battery charge monitor: Regulates the charging of the batteries to make sure it''s happening quickly and efficiently. Notebook connecter: A protected part that allows energy to flow in and

6 FAQs about [Which battery to choose when making lithium battery pack]

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

What are the basic components of a lithium-ion battery pack?

Before diving into the design process, it's crucial to understand the fundamental components of a lithium-ion battery pack: Cells: The basic building blocks of a battery pack. Lithium-ion cells come in various shapes (cylindrical, prismatic, pouch) and chemistries (e.g., NMC, LFP).

How to choose a lithium ion battery?

The lithium-ion battery manufacturer should have a strict gap standard of less 5mv voltage gap, less 15mΩ internal resistance, and less 5mAh capacity gap. To ensure the li-ion battery with a long-lasting cycle and reliable performance, the cell sorting process should be very strict.

Which battery cells are used in a CMB battery pack?

CMB’s battery pack designer gives priority to the following three most common battery cells for the battery pack design: INR (Ternary Lithium), LFP (Lithium Iron Phosphate Chemistry) and LiPo (Lithium Polymer).

How safe is a lithium-ion battery pack?

Safety is paramount in lithium-ion battery pack design. Here are some key safety considerations: Overcharge Protection: Implement safeguards to prevent overcharging, which can lead to thermal runaway and fire. Over-Discharge Protection: Prevent cells from discharging below their safe voltage limit to avoid permanent damage.

What is advanced lithium battery pack design?

Advanced Lithium Battery Pack Design: These custom batteries are made when the customer has special requests for temperature capabilities, dimensions, discharge current, and/or battery cycles. In this case, our chemistries, enclosure, and battery management system (BMS) experts are required to monitor each project closely.

More industry information

- Palestine 48v power frequency inverter

- Wholesale of photovoltaic energy storage integrated machine

- Lithium battery energy storage product grouping standards

- How much does a Russian outdoor power supply cost

- Electrical Engineering New Energy Power Generation and Energy Storage

- Huawei Cameroon energy storage lithium battery

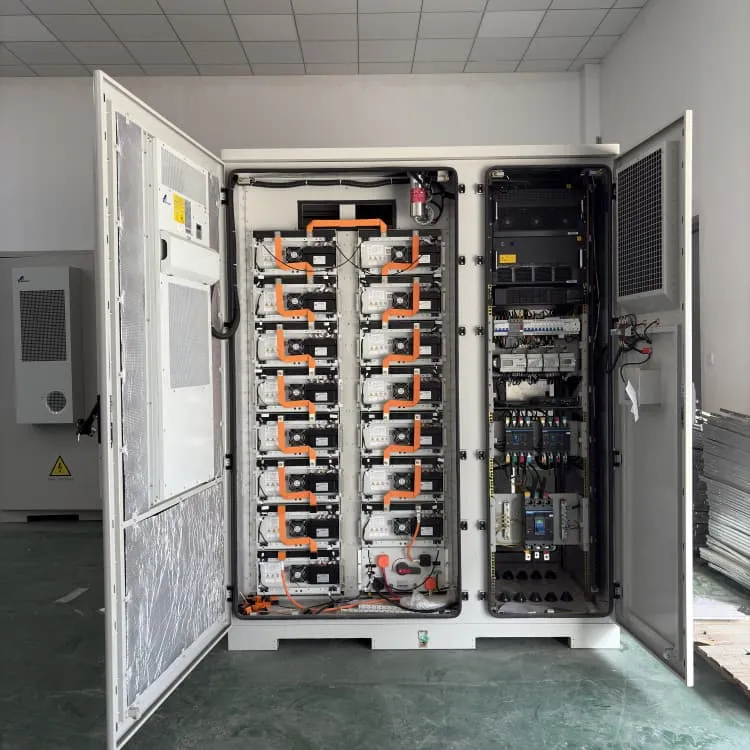

- Energy storage container battery cabinet installation process

- What is a BMS Energy Storage System

- Energy storage power station construction and transmission and distribution network

- Price of home solar integrated system in Brazil

- Energy storage container configuration customization

- Niue three-phase inverter device

- What are the new energy storage power stations in the Middle East

- High power IPM inverter

- 6 watt 12 volt solar

- Industrial and commercial energy storage with outdoor cabinets

- South Africa Photovoltaic Panel Capacity Expansion Manufacturer

- Huawei Algeria Energy Storage Container

- Cambodia s energy storage battery reserves

- Soundproof photovoltaic curtain wall

- $200 Solar Water Pump Inverter

- Solar power systems in Latvia

- West African Photovoltaic Power Generation Equipment Inverter

- Sufficient power monocrystalline silicon photovoltaic panels

- Where to buy new energy battery cabinets at the cheapest

- Sudan Power Energy Storage Vehicle Price Comparison

- Huawei professional outdoor power supply brand