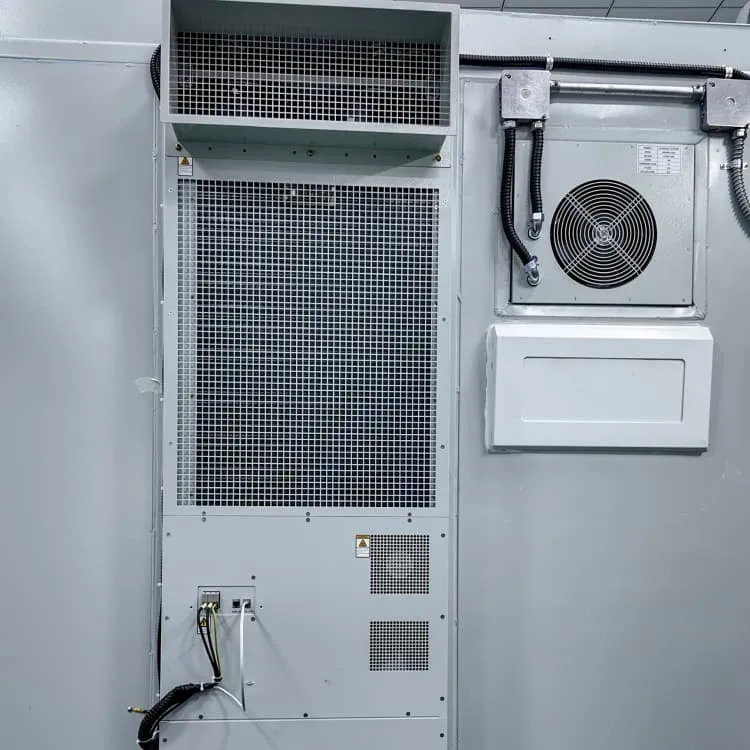

Battery cabinet cold plate production integrated system

Design of the Battery Thermal Management System With Phase

<p>The battery thermal management system with phase change material coupled cold plates was investigated with the numerical simulation method. The results show that, the temperature and

Battery Solutions | BTM for EVs | Chillers, Cold Plates, Integrated

Our offerings include Battery Chillers, Water-cooled Condensers, Cold Plates, and Integrated Thermal Management Modules-each engineered to deliver efficient cooling and heating for EV

Which process improvements have the greatest impact on cost

Discover proven strategies for reducing production costs in battery liquid cold plate manufacturing. This overview covers everything from material selection and design optimization to integrated

Structural design and multi-criteria evaluation of refrigerant-based

Refrigerant-based cold plates (RCP) are increasingly attracting attention for their high heat transfer efficiency, robust thermal safety, and superior integration capabilities. This

Battery Plate Production: Stepping Up with a Continuous Pasting

This thoughtful design reduces the downstream labor intensity and ensures plates are handled correctly from the moment they exit the line, preparing them efficiently perhaps for

A Comparative Life Cycle Analysis of an Active and a Passive Battery

This study extends beyond conventional Battery Thermal Management System (BTMS) research by conducting a Life Cycle Analysis comparing the environmental impacts of

Additive Manufacturing of Battery Thermal Plates: Enhancing EV

Customization and Low-Volume Production: Additive manufacturing is ideal for producing customized thermal plates for specific battery pack designs or for low-volume production runs,

Designing a Battery Cooling Plate: Strategies & Innovations

This article will focus on EV battery cooling plates and cold plate design. Proper thermal management systems are required to prevent excessive heating during speed charges or

Balancing performance and manufacturability in battery cooling plates

According to feedback from the company''s production department manager, it is now possible to achieve integrated delivery of the entire process from design, simulation,

6 FAQs about [Battery cabinet cold plate production integrated system]

What is a direct cold plate?

Introducing the Direct Cold Plate, an efficient heat exchange system utilizing refrigerant to rapidly dissipate heat from battery applications to the air conditioning system. Our versatile design offers three distinct structures, ensuring it meets a wide range of customer requirements.

What is a battery cooling plate?

A battery cooling plate is a flat component manufactured from thermally conductive materials like aluminum or copper. Its function efficiently removes excess heat generated during the battery's fast charging and discharging processes. Two simple schemes will show what is a cold plate and the main principles of thermal management.

How do cooling plates improve battery safety?

Cooling plates effectively manage temperature, enhancing battery system safety. By preventing overheating and thermal runaway events, cooling plates reduce the risk of battery fires or explosions, especially in high-stress environments like electric vehicles or grid storage systems. source: RSC Adv., 2017, 7, 14360-14371

What is a cooling plate & how does it work?

The cooling plates are categorized by side cooling and bottom cooling variants, collectively offering effective cooling for their respective batteries. Introducing the Direct Cold Plate, an efficient heat exchange system utilizing refrigerant to rapidly dissipate heat from battery applications to the air conditioning system.

What are the different types of battery liquid cooling plates?

We have developed various types of battery liquid cooling plates to optimize cooling efficiency. Each type is specifically designed for different battery types. The cooling plates are categorized by side cooling and bottom cooling variants, collectively offering effective cooling for their respective batteries.

How CAD & CAE can be used in cold plate design?

3D simulation involves CAD and CAE tools to analyze detailed thermal system models, enabling precise thermal performance and structural integrity evaluation under realistic conditions. Integrating Artificial Intelligence (AI) and Deep Learning (DL) in cold plate design accelerates the exploration of the design space.

More industry information

- Which photovoltaic energy storage company is best in Sudan

- Privately build a communication base station inverter

- Are silicon wafers used in solar panels

- Canada Photovoltaic Container Substation

- Photovoltaic panels installed on rural roofs in Moldova

- How much does energy storage power cost in North Africa

- Canada photovoltaic curtain wall prices

- Requirements for energy storage power stations in Moldova

- Morocco Inergy Photovoltaic Panel Prices

- One-to-two micro-inverters

- Asia Commercial Energy Storage Battery System

- Inverter power module

- 5v 6w solar panel photovoltaic

- Latvia s solar and wind hybrid system

- Yaounde Silver-based Carbon Battery Cabinet

- Portable power supply DC output

- Home stackable energy storage device

- What are the energy storage systems for power stations

- Power supply price of solar system

- Smallest energy storage power station

- Uzbekistan reliable energy storage container for sale

- Grid Energy Storage Solar Dual Container

- How much does a home inverter cost in Latvia

- The largest solar panel manufacturer

- Is Chile s lithium battery energy storage rate low

- Yemen photovoltaic curtain wall supplier

- Designing a campus solar cell system