How to make battery cabinet production equipment

From Raw Materials to Reliable Power: Inside the Energy Storage

Ever wondered what goes into creating those sleek battery cabinets powering solar farms or backup systems? The energy storage equipment production process is like baking a multilayer

How to Produce Energy Storage Equipment Cabinets: A Maker''s

Let''s cut through the jargon - producing energy storage cabinets isn''t just about welding metal boxes. It''s like building the Swiss Army knife of power systems, where safety marries efficiency

How To Choose The Battery Test Equipment? 5 Proven Tips

5 hours ago· 5 Professional tips to selecting battery test equipment: precision, software, data analytics, expandability and safety for R&D, formation and production QA.

Brief Introduction To Machines Used In Battery Manufacturing

Battery manufacturing is a sophisticated endeavor requiring a diverse range of specialized machines. From material preparation to cell assembly, testing, and quality control,

Battery Manufacturing Process: Materials, Production & Test

This guide covers the entire process, from material selection to the final product''s assembly and testing. Whether you''re a professional in the field or an enthusiast, this deep

UPS Battery Cabinet Upgrade, Retrofit, Replacement

UPS Battery Upgrade, Retrofit, and Replacement At Mitsubishi Electric, we have the products and expertise to guide you through battery and battery cabinet/rack decisions to promote the life

Battery cabinets are process materials

This article describes Eabel''''s custom battery cabinet designed for the lithium-ion battery industry. It highlights the cabinet''''s features, safety considerations, and space utilization capabilities.

See How We Build It: #BSLBATT C&I Battery Cabinet Production

We''re pulling back the curtain to show you exactly how BSLBATT''s robust Commercial & Industrial (C&I) battery cabinets are made – from the core cell technology to the

Battery cells to high-voltage battery cabinets! Factory live production

🔋⚡Explore the core production line of the energy storage factory! 🏭From battery cell sorting, module welding to cabinet integration, the precision manufact...

Battery Cabinet Cost Structure and Optimiza-tion

The main method for gathering data about the cost structures was to interview the subcontractor and people involved in the design process of a battery cabinet, e.g. mechanical engineers.

The Ultimate Guide to Lithium-Ion Battery Storage Cabinets

Discover the importance of lithium-ion battery storage cabinets for safe battery storage and charging. Learn best practices, key features, and how to choose the right battery

How To Make A Lithium Battery Pack With 18650 Cells

In this video I show you how to make your own custom lithium battery pack using the common 18650 lithium cell. I talk about how to connect the cells in series to get the desired voltage you need

6 FAQs about [How to make battery cabinet production equipment]

How to build a battery cabinet?

Step 1: Use CAD software to design the enclosure. You must specify all features at this stage. Step 2: Choose suitable sheet metal for the battery box. You can choose steel or aluminum material. They form the perfect option for battery cabinet fabrication. Step 3: With the dimension from step 1, cut the sheet metal to appropriate sizes.

What is the battery manufacturing process?

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This guide covers the entire process, from material selection to the final product’s assembly and testing.

How to install a battery storage cabinet?

Mounting mechanism – they vary depending on whether the battery storage cabinet is a pole mount, wall mount, or floor mount. The mechanism allows you to install the battery box enclosure appropriately. Racks – these systems support batteries in the enclosure. Ideally, the battery rack should be strong.

How do you choose a battery cabinet?

Again, the door should have a safe locking mechanism or latch. In more advanced battery cabinets, they may have alarm systems. Ventilation systems – they may integrate louvers. Depending on the enclosure design, the ventilation systems can be at the top or bottom section. Ventilation systems also help during the cooling process.

What makes a successful battery pack manufacturing process?

Effective cell selection and procurement lay the groundwork for successful battery pack manufacturing, directly impacting the quality and performance of the final product. The battery cell manufacturing process is a complex, multi-step procedure that ensures the efficiency, safety, and longevity of battery packs.

What are the parts of a battery storage cabinet?

Let’s look at the most common parts: Frame – it forms the outer structure. In most cases, you will mount or weld various panels on the structure. The battery storage cabinet may have top, bottom, and side panels. Door – allows you to access the battery box enclosure. You can use hinges to attach the door to the enclosure structure.

More industry information

- Huawei Belgium Industrial and Commercial Energy Storage Cabinet Manufacturer

- Heishan Outdoor Wind Power Base Station Company

- Solar water pump inverter sound insulation

- Latest on energy storage for communication base stations

- Solar integrated wall mounted home appliance

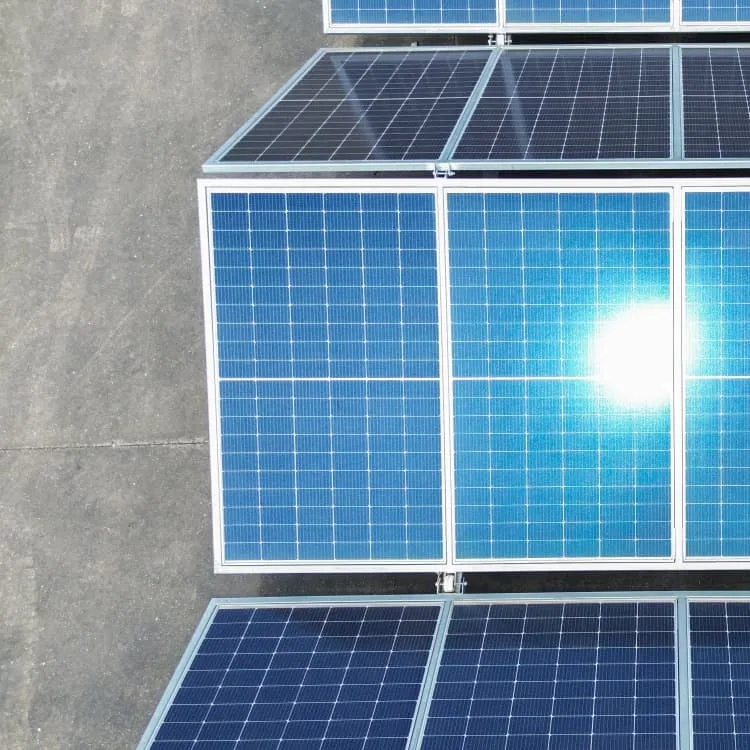

- Supply and demand for solar panels

- High-end photovoltaic power generation hollow solar panels

- Hybrid energy storage project industrial park

- Iraq emergency energy storage power supply price

- What are the EMS projects for communication base stations

- 6v 20w solar photovoltaic panel current

- What brands of energy battery cabinets are there at the Maldives site

- Mauritania Industrial Lithium Battery Pack

- Customized cost of lithium battery station cabinets in Western Europe

- Solomon Islands flexible photovoltaic panels

- Requirements for energy storage power stations in industrial parks

- Bahamas Battery Site Cabinet Integration System

- Nicaragua Energy Storage Device

- Rwanda outdoor container power generation

- 500W retractable solar panel

- Northern European companies that make solar panels

- Ukrainian large energy storage prices

- Philippines Distributed Energy Storage Project

- 48v 18ah outdoor battery cabinet

- Lithium batteries and energy storage cabinet batteries

- Inverter 48v recommended

- Pure sine wave inverter price