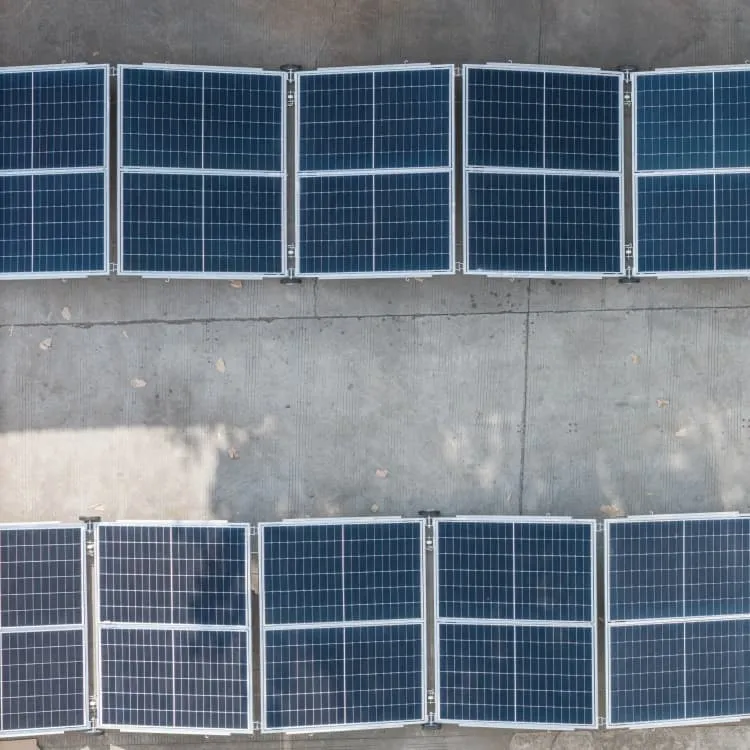

Double glass multicrystalline silicon cell components

Solar Cells on Multicrystalline Silicon Thin Films Converted from

Fabrication and characterization of solar cells based on multicrystalline silicon (mc-Si) thin films are described and synthesized from low-cost soda-lime glass (SLG).

Photovoltaic Cell Generations and Current Research Directions

In particular, the third generation of photovoltaic cells and recent trends in its field, including multi-junction cells and cells with intermediate energy levels in the forbidden band of silicon, are

Selection of Materials for Double Layer Antireflection Coating

ABSTRACT In present work an attempt has been made to select material to design double layer antireflection coatings (DLARC) for silicon solar cell, theoretically. In this regard, silicon nitride

Solar Cells on Multicrystalline Silicon Thin Films Converted from

Fabrication and characterization of solar cells based on multicrystalline silicon (mc-Si) thin films are described and synthesized from low-cost soda-lime glass (SLG). The

Silicon solar cells: materials, technologies, architectures

This chapter reviews the field of silicon solar cells from a device engineering perspective, encompassing both the crystalline and the thin-film silicon technologies. After a

SIOxNy – SINx DOUBLE ANTIREFLECTION LAYER FOR

On polished surfaces, these optimized structures have the potential to increase the short-circuit current by more than 2% for non-encapsulated cells and up to 0.5% for encapsulated cells, in

Understanding Process-related Efficiency Variations of

The majority of solar modules contain crystalline silicon solar cells which can be described by their respective power and efficiency. Usually power and efficiency of the assembled photovoltaic

Double-side textured liquid phase crystallized silicon thin-film

In this paper, we present recent advances and challenges of a light management concept for liquid phase crystallized 10 µm-thick silicon films on imprinted glass substrates

a-Class 640W 665W Monocrystalline Silicon Double-Sided Double Glass

a-Class 640W 665W Monocrystalline Silicon Double-Sided Double Glass Perc Solar Panel, Find Details and Price about Solar Panel Module Half Cell Monocrystalline Panel from a-Class

Multicrystalline Silicon Solar Cell Manufacturing

The manufacturing process typically involves directional solidification of molten silicon, where controlled grain growth and impurity management are critical to achieving high conversion...

Impact of Cracks in Multicrystalline Silicon Solar Cells on PV

In this paper, we present a methodology to exploit the crack statistics of solar cells in photovoltaic (PV) modules assessed in field for simulating the power output of PV modules

Multi Crystalline Silicon, Multicrystalline, Ingot Company 丨DSTC

The Multi-Crystalline Silicon Ingot from DSTC is perfect for high-efficiency multi crystalline silicon solar cell applications. Our multicrystalline ingots offer superior quality and competitive ingot

Enhancing Optoelectronic Properties of Multicrystalline Silicon

In this study, a dual treatment combining porous silicon and texturing was employed as an effective approach to enhance the optical and optoelectronic properties of mc

The degradation of multi-crystalline silicon solar cells after damp

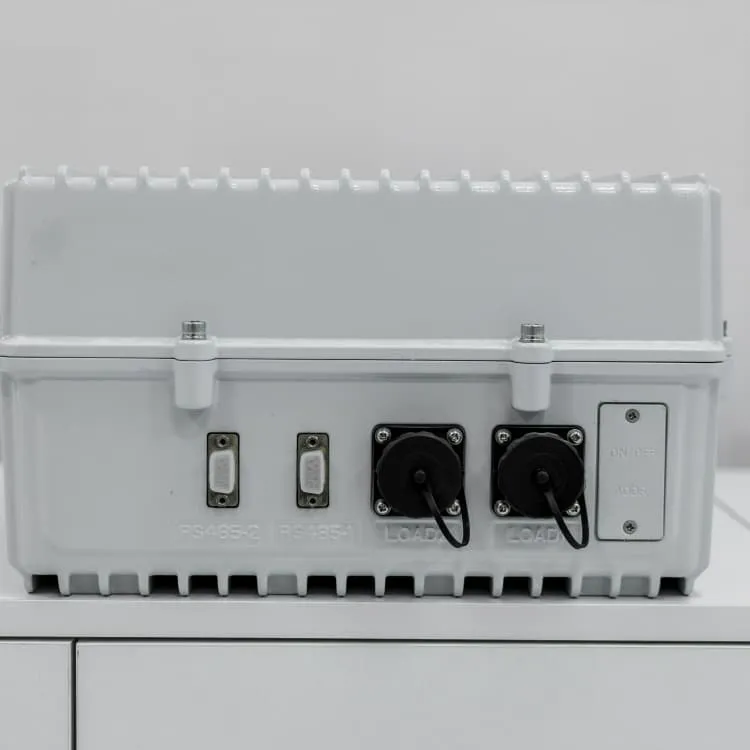

The key factor for excellent performance of Si wafer-based double glass PV modules is replacing the polymer backsheet by a glass panel with impermeability to water

SiO2 surface passivation layers – a key technology for silicon solar cells

High-efficiency silicon solar cells strongly rely on an effective reduction of charge carrier recombination at their surfaces, i.e. surface passivation. Today''s industrial silicon solar

6 FAQs about [Double glass multicrystalline silicon cell components]

How are multicrystalline cells made?

Multicrystalline cells are produced using numerous grains of monocrystalline silicon. In the manufacturing process, molten multicrystalline silicon is cast into ingots, which are subsequently cut into very thin wafers and assembled into complete cells.

What is a multicrystalline silicon cell?

Multicrystalline silicon cells. Multicrystalline cells, also known as polycrystalline cells, are produced using numerous grains of monocrystalline silicon. In the manufacturing process, molten polycrystalline silicon is cast into ingots, which are subsequently cut into very thin wafers and assembled into complete cells.

How molten polycrystalline silicon is made?

In the manufacturing process, molten polycrystalline silicon is cast into ingots, which are subsequently cut into very thin wafers and assembled into complete cells. Multicrystalline cells are cheaper to produce than monocrystalline ones because of the simpler manufacturing process required.

What is a monocrystalline silicon solar cell?

Monocrystalline silicon solar cells involve growing Si blocks from small monocrystalline silicon seeds and then cutting them to form monocrystalline silicon wafers, which are fabricated using the Czochralski process (Figure 4 a). Monocrystalline material is widely used due to its high efficiency compared to multicrystalline material.

What is a crystalline silicon cell?

Crystalline silicon cells are further categorized as either monocrystalline silicon cells that offer high efficiencies (13–19%) but are more difficult to manufacture or polycrystalline (also called multicrystalline) silicon cells that have lower efficiencies (9–14%) but are less expensive and easier to manufacture.

What is mc-Si crystalline silicon synthesis (CSS)?

A residual composite layer of mainly alumina and unreacted Al forms beneath the mc-Si thin film as the second product of the crystalline silicon synthesis (CSS) process, which can be used as rear contact in a vertical solar cell design.

More industry information

- Power frequency inverter voltage adaptation

- Cambodia energy storage equipment prices

- Container distribution cabinet manufacturer

- National communication green base station hybrid power supply

- Senegal s largest solar photovoltaic panel manufacturer

- Solar all-in-one home use manufacturer

- Swaziland photovoltaic energy storage system integrated photovoltaic storage device sales

- Does new energy have to be equipped with energy storage stations

- Hungarian energy storage battery manufacturing

- Which base station power supply is better

- How many watts does an outdoor solar all-in-one machine usually have

- Iranian lithium battery brand

- Island Energy Storage Container Factory

- What is the price of Hungarian inverters

- Afghanistan energy storage high power supply wholesale price

- Photovoltaic curtain wall sun room

- Hungarian ipm intelligent inverter manufacturer

- Wind-solar complementarity and energy storage

- China-Africa Power Energy Storage Vehicle Price Comparison

- How much does a container energy storage cabinet cost in Cyprus

- Is energy storage project considered infrastructure

- Swiss Photovoltaic Solar Panel Factory

- What is the outdoor power supply number in Mexico

- Charging pile energy storage price trend

- Europe s largest energy storage battery company

- What does packing lithium batteries mean

- Abkhazia invests in grid-side energy storage power station