Maximum temperature difference of air-cooled energy storage container

Maximum temperature difference of air-cooled energy storage container

The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research. This paper innovatively proposes an optimized

Integrated cooling system with multiple operating modes for

Generally, the temperature difference between batteries in the container does not exceed 3 °C. When the temperature difference between batteries is greater than 10 °C, the

Modeling and analysis of liquid-cooling thermal management of

The experimental results corroborate the effectiveness of the liquid cooling BTMS; the maximum temperature rise of the batteries during the discharging and charging processes

Structural design and optimization of air-cooled thermal

The power battery thermal management system plays a crucial role in controlling battery pack temperature and ensuring efficient battery operation. The optimal design of the structure of the

Maximum Temperature Difference in Air-Cooled Energy Storage Containers

The maximum temperature difference – that critical gap between a system''s hottest and coldest points – directly impacts safety, efficiency, and equipment lifespan....

Efficient Cooling System Design for 5MWh BESS Containers:

Discover the critical role of efficient cooling system design in 5MWh Battery Energy Storage System (BESS) containers. Learn how different liquid cooling unit selections impact

Integrated cooling system with multiple operating modes for temperature

Generally, the temperature difference between batteries in the container does not exceed 3 °C. When the temperature difference between batteries is greater than 10 °C, the

Liquid-cooled energy storage rear lead-acid battery box

The three liquid-cooled plates are numbered from top to bottom as No. 1 liquid-cooled plate, No. 2 liquid-cooled plate and No. 3 liquid-cooled Optimization studies The BTMS III with the lowest

Maximum temperature difference of air-cooled energy storage

The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research. This paper innovatively proposes an optimized

Full-scale simulation of a 372 kW/372 kWh whole-cluster

The maximum temperature and temperature difference were reduced by 0.5 °C and 0.6 °C, respectively. Liu et al. [30] utilized the morphology of the 18650 batteries itself to

Experimental and numerical investigation of a composite thermal

Abstract Traditional air-cooled thermal management solutions cannot meet the requirements of heat dissipation and temperature uniformity of the commercial large-capacity

Integrated cooling system with multiple operating modes for temperature

Aiming at the problem of insufficient energy saving potential of the existing energy storage liquid cooled air conditioning system, this paper integrates vapor compression

Cooling Characteristics and Optimization of an Air-Cooled Battery

Lithium-iron phosphate batteries are widely used in energy storage systems and electric vehicle for their favorable safety profiles and high reliability. The designing of an

6 FAQs about [Maximum temperature difference of air-cooled energy storage container]

How much energy does a container storage temperature control system use?

The average daily energy consumption of the conventional air conditioning is 20.8 % in battery charging and discharging mode and 58.4 % in standby mode. The proposed container energy storage temperature control system has an average daily energy consumption of 30.1 % in battery charging and discharging mode and 39.8 % in standby mode. Fig. 10.

What is a container energy storage system?

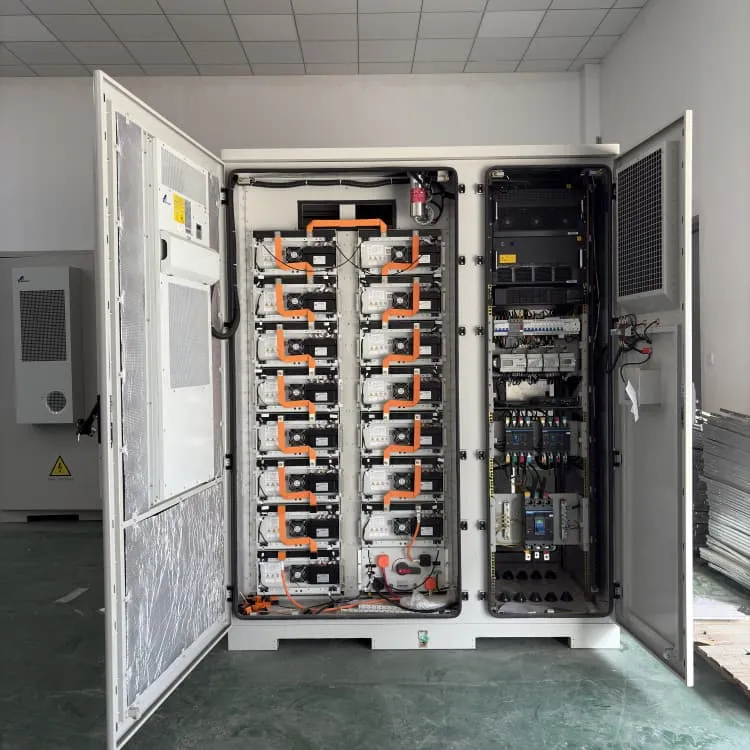

Containerized energy storage systems play an important role in the transmission, distribution and utilization of energy such as thermal, wind and solar power [3, 4]. Lithium batteries are widely used in container energy storage systems because of their high energy density, long service life and large output power [5, 6].

What is a composite cooling system for energy storage containers?

Fig. 1 (a) shows the schematic diagram of the proposed composite cooling system for energy storage containers. The liquid cooling system conveys the low temperature coolant to the cold plate of the battery through the water pump to absorb the heat of the energy storage battery during the charging/discharging process.

How much power does a containerized energy storage system use?

In Shanghai, the ACCOP of conventional air conditioning is 3.7 and the average hourly power consumption in charge/discharge mode is 16.2 kW, while the ACCOP of the proposed containerized energy storage temperature control system is 4.1 and the average hourly power consumption in charge/discharge mode is 14.6 kW.

Do cooling and heating conditions affect energy storage temperature control systems?

An energy storage temperature control system is proposed. The effect of different cooling and heating conditions on the proposed system was investigated. An experimental rig was constructed and the results were compared to a conventional temperature control system.

How to choose a compressor for a container energy storage battery?

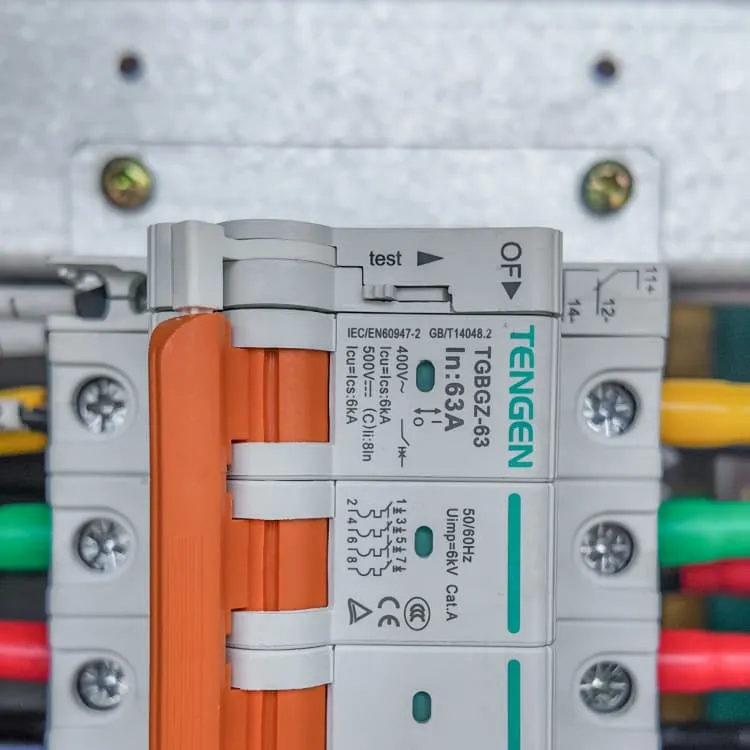

In view of the temperature control requirements for charging/discharging of container energy storage batteries, the selection of the compressor is based on the rated operating condition of the system at 45 °C outdoor temperature and 18 °C water inlet temperature to achieve 60 kW cooling capacity.

More industry information

- Slovakia s new energy project supporting energy storage

- 16 square solar panel price

- Somaliland Power Supply Communication Base Station

- Malta Mobile Power Station BESS

- Romanian solar base station brand manufacturer

- Liberia Communications BESS Power Station Manufacturer

- Solar panels 12v on-site energy

- Which is the best double-glass photovoltaic curtain wall in Kyrgyzstan

- Huawei Romania energy storage photovoltaic products

- Household Energy Storage Battery Quote

- Photovoltaic civilian energy storage battery

- Swaziland Energy Storage Container Design

- Inverter 48v can be converted to 12v

- Flow battery prices in Botswana

- Photovoltaic factory in the Democratic Republic of Congo produces solar panels

- Is photovoltaic panel power generation useful

- Cook Islands Photovoltaic Power Inverter

- Huijue Energy Storage Container Production

- Energy storage cabinet stops supplying power

- How big an outdoor power supply should a household use

- Light outdoor battery cabinet 220v

- The first battery in the lithium battery pack discharges quickly

- Heishan Home Energy Storage Manufacturer

- Balcony photovoltaic solar panels

- How many watts should a photovoltaic solar installation take

- Which is the best home energy storage in Iceland

- Malaysia Solar Mobile Home Purchase