Wacker Group Solar Cells

"We''re Halving Our CO2 Emissions by 2030"

It''s the most important starting material for solar cells. You can''t produce silicon-based solar cells without our material. On the other hand, we have products that support new environmentally

Solar Modules in Dubai – A Success Story

Energy from the region, for the region – that was the idea behind a sustainability project at our office in Dubai. Solar panels over parking lots and on the roof of the building now supply the

More non-Chinese solar polysilicon is being sent to Vietnam to

"The non-Chinese polysilicon manufacturers Wacker, Hemlock Semiconductor and OCI Malaysia are increasingly shifting their shipments from China to Vietnam, where three of

#MakeSolarEU: WACKER''s role in reshoring solar manufacturing

Polysilicon is at the heart of every solar cell and the basis for every semiconductor chip. We are the only globally relevant producer of polysilicon in Europe and the largest

Top 10 Companies in the Photovoltaic Materials Industry (2025):

3 days ago· Here we analyze the Top 10 Companies in the Photovoltaic Materials Industry – a group of silicon specialists, material chemists, and next-gen technology developers steering

6 FAQs about [Wacker Group Solar Cells]

Is Wacker a future-proof solar company?

Today the company offers the solar industry a portfolio of future-proof products along the entire solar value chain. WACKER is a world market leader in polysilicon, with production sites in Burghausen, Nünchritz and Charleston and an annual production capacity of up to 80,000 metric tons.

What makes Wacker a good partner for the solar industry?

As a leading manufacturer of polysilicon and a pioneer in silicones, WACKER has been an important partner of the solar industry since its beginning. Today the company offers the solar industry a portfolio of future-proof products along the entire solar value chain.

Why should you choose Wacker?

WACKER's hyperpure silicon for the production of solar cells as well as its pyrogenic silica and innovative silicone products for solar, wind and hydro power applications offer the renewable energy industry a product portfolio that covers the entire supply chain and is fit for the future.

What is Wacker Polysilicon & how does it work?

Companies like Wacker use the Siemens process to remove the remaining impurities. The resulting polysilicon is a crystallized form of silicon that needs to be at least 99.9999% pure for solar applications—and even purer for computer chips.

Where is Wacker Polysilicon made?

WACKER is a world market leader in polysilicon, with production sites in Burghausen, Nünchritz and Charleston and an annual production capacity of up to 80,000 metric tons. WACKER has a long history of producing polysilicon, ensuring high and consistent quality.

Does Wacker Chemie have a street system?

Wacker Chemie’s chemical plant in Charleston, Tennessee, is large enough to have its own street system. Lettered streets run roughly east to west, intersecting numbered avenues at perfect 90° angles. The 220-hectare site produces polysilicon, a key material used to make solar panels and computer chips.

More industry information

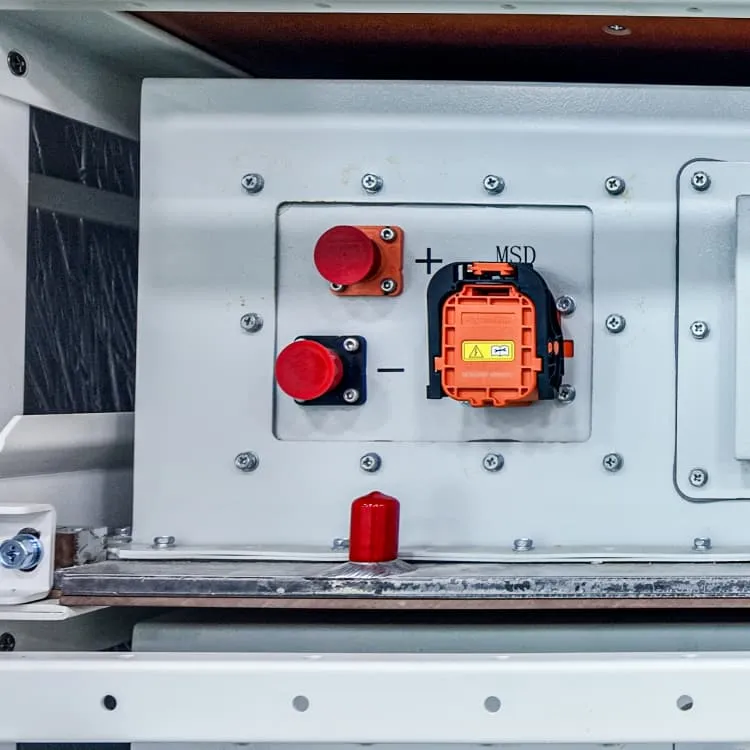

- Nicaragua BMS Battery Management

- Solar Panel Details

- Haiti Phase Change Energy Storage Products

- Relationship between photovoltaic panel temperature and current

- Nanya energy storage container prefabricated cabin merchants

- Energy storage temperature control system

- Advantages of photovoltaic panels for power generation

- The source of electricity for energy storage power stations

- The difference between lithium batteries and energy storage batteries

- Grid-connected solar inverter

- Two outdoor power supplies in parallel

- Ecuador solar panel price per square meter

- China s outdoor energy storage system

- Lesotho yellow battery cabinet manufacturer

- South African household energy storage lithium battery function

- Sine wave inverter modulation

- Which type of battery swap cabinet has the most stations in Tanzania

- Lead content in base station batteries

- Outdoor power supply high power brand

- The future of photovoltaic energy storage batteries

- Power consumption of 5G base stations in Ukraine

- Outdoor 200W solar

- Energy storage device plus inverter

- Georgia Energy Storage Cabinet Equipment Manufacturer Ranking

- Moroccan energy storage inverter manufacturer

- Which company is best for Iceland s energy storage containers

- Brazil Communications begins building 5G base stations