Energy Storage Liquid Cooling Container Design

CubeArk-Liquid Cooling 215Kwh 430Kwh 645Kwh 699Kwh

The liquid cooling system ensures higher system efficiency and cell cycling up to 10,000 cycles. The liquid cooling system reduces system energy consumption by 20% and extends battery

Energy Storage Liquid Cooling Container Design: The Future of

Spoiler: It''s not just about keeping things chill. Energy storage liquid cooling container design is the unsung hero behind reliable renewable energy systems, electric

Efficient Cooling System Design for 5MWh BESS Containers:

Discover the critical role of efficient cooling system design in 5MWh Battery Energy Storage System (BESS) containers. Learn how different liquid cooling unit selections impact

Liquid-Cooled Energy Storage System Architecture and BMS Design

As the demand for high-capacity, high-power density energy storage grows, liquid-cooled energy storage is becoming an industry trend. Liquid-cooled battery modules, with large capacity,

Liquid Cooling BESS Container, 5MWH Container Energy

Designed for efficiency and ease of use, this energy storage container system offers minimalist operation and maintenance, making it an attractive choice for industries that prioritize cost

Liquid Cooling BESS Container, 5MWH Container Energy Storage

Designed for efficiency and ease of use, this energy storage container system offers minimalist operation and maintenance, making it an attractive choice for industries that prioritize cost

Liquid-cooled Energy Storage Cabinet

Commercial & Industrial ESSExcellent Life Cycle Cost • Cells with up to 12,000 cycles. • Lifespan of over 5 years; payback within 3 years. • Intelligent Liquid Cooling, maintaining a temperature

Study on uniform distribution of liquid cooling pipeline in container

Designing a liquid cooling system for a container battery energy storage system (BESS) is vital for maximizing capacity, prolonging the system''s lifespan, and improving its

2.5MW/5MWh Liquid-cooling Energy Storage System Technical

The project features a 2.5MW/5MWh energy storage system with a non-walk-in design which facilitates equipment installation and maintenance, while ensuring long-term safe and reliable

Liquid Cooling in Energy Storage: Innovative Power Solutions

This article explores the benefits and applications of liquid cooling in energy storage systems, highlighting why this technology is pivotal for the future of sustainable energy.

Liquid Cooling System Design, Calculation, and Testing for Energy

Explore the application of liquid cooling in energy storage systems, focusing on LiFePO4 batteries, custom heat sink design, thermal management, fire suppression, and testing validation

6 FAQs about [Energy Storage Liquid Cooling Container Design]

What is a 5MWh liquid-cooling energy storage system?

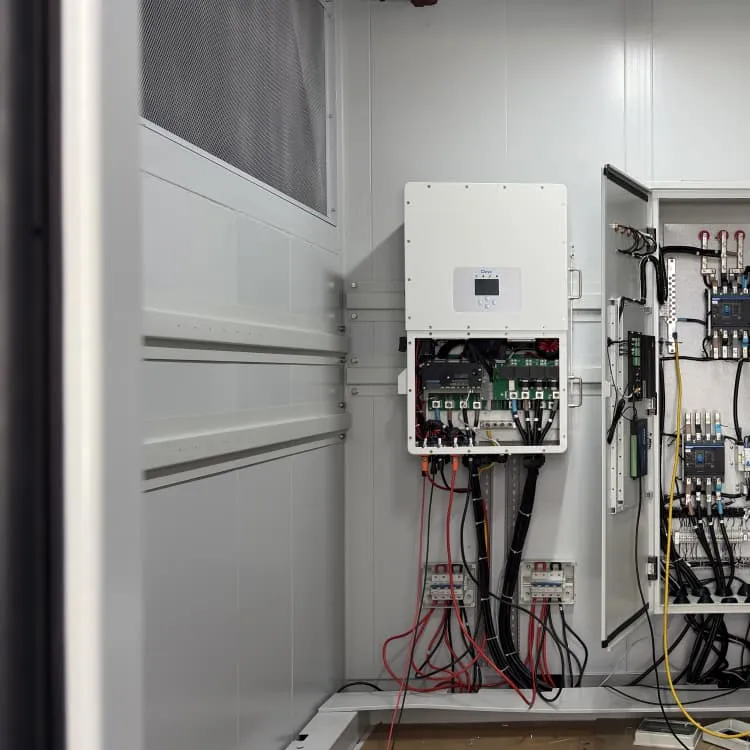

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20’GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring harness, and more. And, the container offers a protective capability and serves as a transportable workspace for equipment operation.

How are energy storage batteries integrated in a non-walk-in container?

The energy storage batteries are integrated within a non-walk-in container, which ensures convenient onsite installation. The container includes: an energy storage lithium iron phosphate battery system, BMS system, power distribution system, firefighting system, DC bus system, thermal management system, and lighting system, among others.

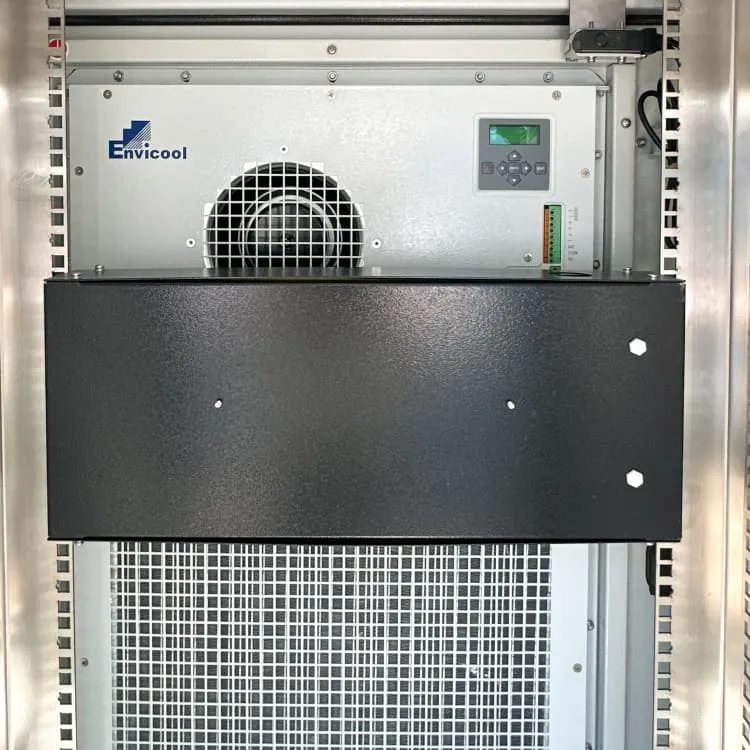

What is a liquid cooling unit?

The product installs a liquid-cooling unit for thermal management of energy storage battery system. It effectively dissipates excess heat in high-temperature environments while in low temperatures, it preheats the equipment. Such measures ensure that the equipment within the cabin maintains its lifespan.

What is a liquid cooling thermal management system?

The liquid cooling thermal management system for the energy storage cabin includes liquid cooling units, liquid cooling pipes, and coolant. The unit achieves cooling or heating of the coolant through thermal exchange. The coolant transports heat via thermal exchange with the cooling plates and the liquid cooling units.

What is a liquid cooling system?

This project’s liquid cooling system consists of primary, secondary, and tertiary pipelines, constructed by using factory prefabrication and on-site assembly within the cabin. The primary liquid cooling pipes utilize 304 stainless steel, whereas the secondary and tertiary pipes are made from PA12 nylon tubing.

How to choose an energy storage unit?

The choice of the unit should be based on the cooling and heating capacity parameters of the energy storage cabin, alongside considerations like installation, cost, and additional functionalities. 3.12.1.2 The unit must utilize a closed, circulating liquid cooling system.

More industry information

- Guyana s new liquid flow battery

- Energy storage installation cost and electricity cost

- 3 7V to 220V inverter

- PV module BESS price

- Kyrgyzstan energy storage power brand

- Flywheel energy storage structure includes

- German 5G communication energy storage power supply manufacturer

- How many strings are there in a 21 volt lithium battery pack

- Do energy storage batteries require polysilicon

- Bangladesh communication base station power supply equipment customization

- Do I need to turn off the inverter when replacing photovoltaic panels

- China-Europe Photovoltaic Energy Storage Application System

- The power of a 3 kilowatt photovoltaic panel is only 1600

- The world s largest power storage

- What is the price of inverters in Europe

- 1 5kw inverter price

- Cuba Container Energy Storage Information

- Pakistan Commercial Energy Storage Cabinet System

- East Africa Portable Power Supply Manufacturer Supply

- Import of photovoltaic inverters from the Democratic Republic of the Congo

- Algeria energy storage battery

- Peak-valley energy storage system capacity selection

- Making energy storage battery equipment

- Photovoltaic battery energy storage support

- Huawei installs inverters in Slovakia

- What is the power of solar inverter

- Inverter high frequency will cut off power protection